MAP1400 HMC is reporting an installation error before serviceable events being created

This MAP guides you to repair a problem that was found during the 'Install Storage Facility' process and continues with the storage facility installation after the problem is repaired.

Before you begin

CAUTION:

Use this MAP only when you are directed

by the Installation instructions or an on-screen message.

MAP1400 Section-1

Procedure

MAP1400 Section-A

About this task

Procedure

MAP1400 Section-B

About this task

Procedure

MAP1400 Section-C

About this task

Procedure

MAP1400 Section-D

About this task

Procedure

MAP1400 Section-E

About this task

Procedure

- Record any on-screen error messages.

- Contact your next level of support.

MAP1400 Section-F

About this task

Procedure

- Record any on-screen error messages.

- Contact your next level of support.

MAP1400 Section-G

About this task

Procedure

MAP1400 Section-H

About this task

Procedure

MAP1400 Section-I

About this task

Procedure

- Record any on-screen error messages.

- Contact your next level of support.

MAP1400 Section-J

About this task

Procedure

MAP1400 Section-K

About this task

Procedure

- Record the state of the storage facility as displayed in the Storage Facility Install/Remove panel.

- Contact your next level of support.

MAP1400 Section-L

About this task

Procedure

- Ensure that all service actions on this storage facility initiated from the management console were completed or canceled.

- Ensure that all service actions on this storage facility initiated from an alternative management console were completed or canceled.

- Return to the installation process and repeat the operation to perform the 'Field Install Storage Facility'.

- If the problem persists, then contact your next level of support.

MAP1400 Section-M

About this task

Procedure

- Record any on-screen error messages.

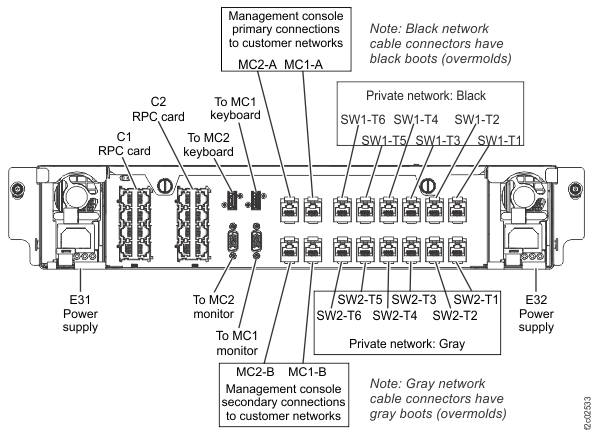

- Verify that the PCN cables are properly connected on both the RPC and the I/O enclosure ends.

- Contact your next level of support.

MAP1400 Section-N

About this task

You were sent to this section because one of the following conditions:

- The storage facility was not listed on the Install/Add/Remove panel. Selection of this panel causes the management console to attempt to 'discover' all attached storage facilities. If the new storage facility is not listed, then it is likely that the management console cannot communicate with the CEC enclosure service processors in the new storage facility. This problem would be expected only when installing a new (second) storage facility to an existing storage complex.

- One or more CEC enclosure managed systems were found in the 'No Connection' state. If a managed system is in the 'No Connection' state, the management console cannot communicate with the service processor in that managed system.

Procedure

MAP1400 Section-P

About this task

Procedure

MAP1400 Section-Q

About this task

Procedure

MAP1400 Section-R

About this task

Procedure

MAP1400 Section-S

About this task

CAUTION:

If you Click on the NO button

in answer to the question "Do you want to continue with the Installation

Process?" then the Field Install Storage Facility process terminates.

The automated process must then be run again from the start to complete

the installation.

Procedure

MAP1400 Section-T

About this task

Procedure

MAP1400 Section-U

About this task

Procedure

MAP1400 Section-V

About this task

Procedure

MAP1400 Section-W

About this task

Procedure

MAP1400 Section-X

About this task

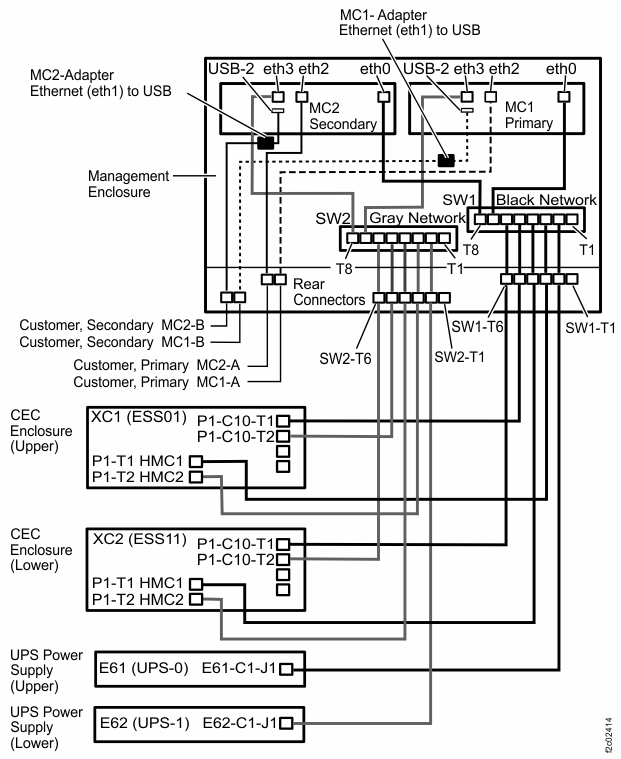

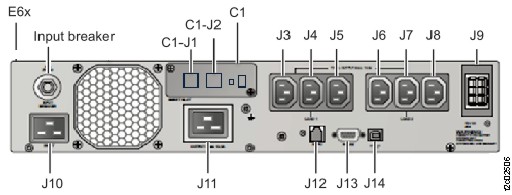

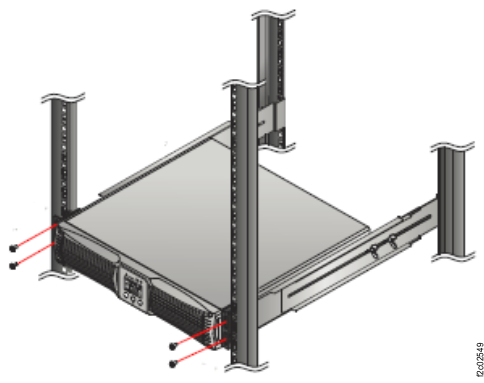

The management console Ethernet connection to both UPS is not responding. Possible causes:

- This MAP section is only for the condition where the management console cannot communicate to both UPS through their network card Ethernet connections. If only a single UPS is failing to communicate this MAP section is not called.

- Each UPS network card Ethernet port is pre-configured in manufacturing with a static IP address, which is used by the management consoles.

The possible causes that a management enclosure could not communicate to both UPS are:

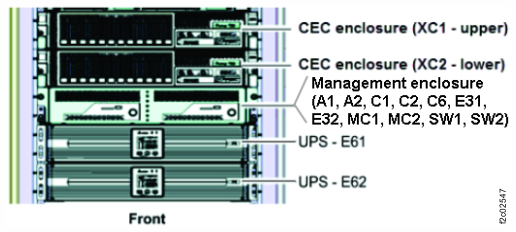

- The UPS were installed in the wrong positions in the rack. (The E61 upper UPS only connects to the black network switch. The E62 lower UPS only connects to the gray network switch.)

- The Ethernet cables to both UPS are disconnected.

- The Ethernet cables to both UPS are misplugged (cross-connected).

being lit solid and the

DC good (output) LED

being lit solid and the

DC good (output) LED  flashing.

flashing.